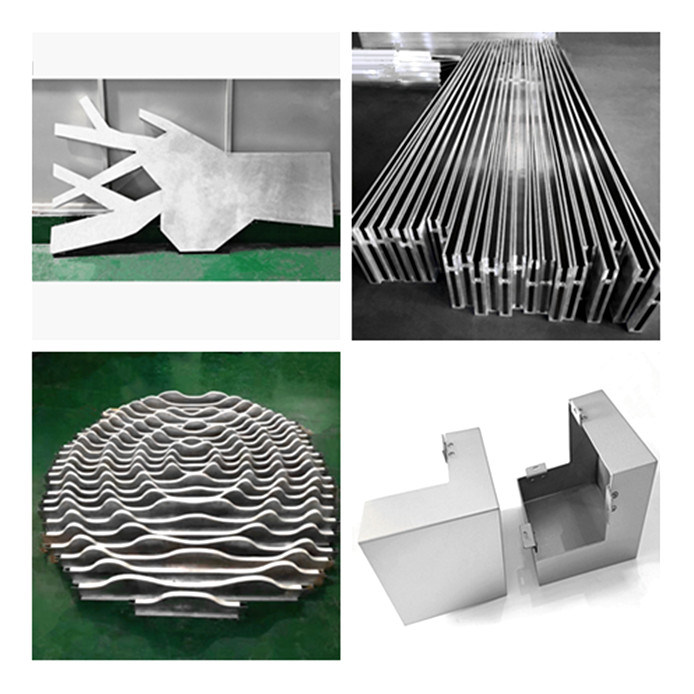

Products Display

Project Case

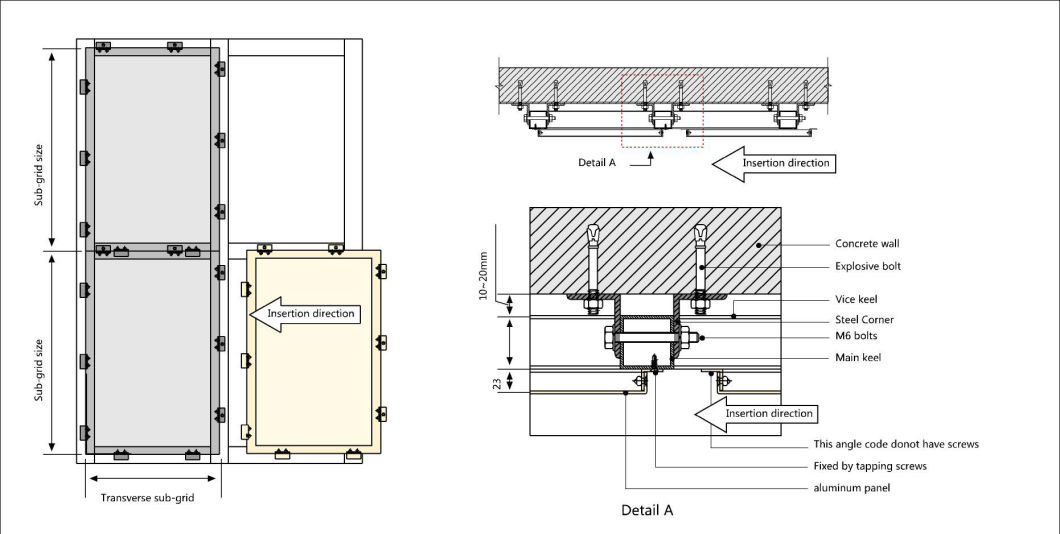

Installation Drawing

Product name | Aluminum carved Panel (Flat Seam) |

Thickness | 1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm, etc. |

Max size | 1800*5000mm (Flat) |

Aluminum alloy | 1100/3003/3105 |

Surface treatment | PE/PVDF spray coating, Powder coating |

Painting | KCC, PPG, Akzo Nobel, Becker, etc |

Color | Solid color, Metallic Color, Wooden/Stone Color, etc |

Size/Design | Sizes and design are available according your detail drawings |

Certificates: | SGS,ISO 9001:2000,CE,KYNAR 500, etc |

MOQ: | 1 sqm for thickness ≤ 3.0mm, 1000 sqm for thickness >3.0mm |

Delivery time: | around 20 days, depends on the panel drawings and quantity |

Payment Term: | TT, LC at sight |

Production Capability: | 50000SQM Per Month |

More Service: | OEM, Small samples free |

Main Production: | Aluminum Single Panel (Flat Seam/Seamless), Square Column Aluminum Cover (Seam/Seamless), Round Column Aluminum Cover (Seam/Seamless), Perforated Aluminum Single Panel, Meshed Aluminum Panel, Carved Aluminum Panel, etc. |

1, Specification:

The thickness of laser cutting carved aluminum panel is decided by the panel size and the height of the building. The thickness we used mostly is from 1-3mm, it is so easy to be proceed into various kinds of sizes and patterns. The carved panel mainly use CNC laser engraving equipment, it is can be made into different ceilings, curtain wall, the hollow pattern of column cover, according to different requirments. Laser Cut Aluminum Cladding Panel Advantage:

1. Light material, high precision

2. Any pattern can be made, no need open dies.

3. easy to clean and maintenance

4. Wonderful colors for your choice

5. Nice looking

6. Good strength than aluminum composite panel

7. Low production cost, save more material

8. Fireproof, moisture proof, mould proof

9. Corrosion resistance,Hi-strength

2. Applications:

1)Interior wall cladding

2)Exteror wall cladding

3)Ceiling panel

4)Aluminum fence

5)Other decoration area

3. Why choose us ?

1, Mission:Focus On Customer's request and offer the Best Quality and Service!

2, Vision: Improve our own brand's quality and reputation .

To be one of the best OEM factories in this field ,and set up good sales net in the domestic and overseas market

3,Brief introduction:

We are experienced and energetic team!

- average age is 26 years old,we know the development trend of the Decoration materials!

- set up since 1996, have the rich experience in the production and international sales!

- always focus on The customer's request.

4, We are the manufacturer !

- Industrial design team makes the project design more fashion!

- engineer team makes the project more safe !

- QC team makes the products more qualified!

-factory with hundreds professional workman,make manufacture more efficiently!

5. FAQ

1, Q:Are you manufacture or simply trading company ?

A: We are the manufacture , welcome you visit our factory.

2,Q: Do you provide free samples ?

A:We do provide free samples under the condition that you assume the express shipping cost

3,Q: How to place order ?

A: Please tell us the service you need, OEM or ODM, and the quantity , then we will make the PI for you.

4,Q: How did you test the product before they are packed?

A :We have the strict QC procedure , each product will be tested by three times with professional machine before packing.

5,Q:What's the delivery time ?

A: Usually 15-20 days after receiving deposit .

6,Q:Where is the shipping port ?

A:We ship the products via Huangpu port, Guangzhou or any other ports depend on your needs.

7,Q: What about the payment terms ?

A: 30% TT advanced payment , balance need to pay before shipment.