Wall advertising aluminum signage composite panels MANUFACTURER

8 Advantages of Neitabond

1)Complete Product Series with competitive price

2)Prompt lead time:10-15 working days after deposite.31500sq.m per day with 7high speed production lines.

3)Complete inspection system

4)Official Cettificates:ISO by TUV,BV,ASTM E84

5)Complete After-sales service system

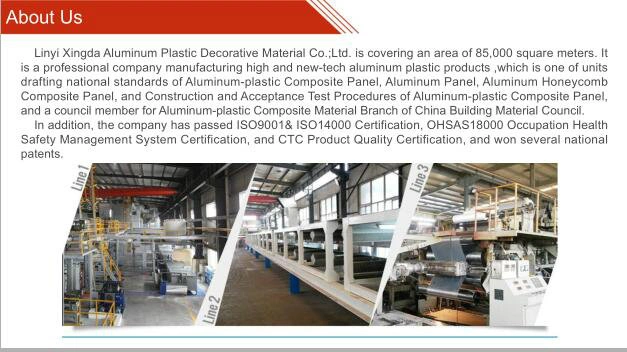

6)Direct factory,14 years experience:Neitabond,since 2003

7)Honors:"Famous brand in Shandong Province","Credible enterprise"etc.All honors that we are reliable partner.

8)Free OEM Service

| Description | Test standard | PVDF |

| Thickness of coating | PVDF paint>=25um | 28um to 32um |

| Coating flexibility (T-bend) | PVDF paint≥2T | 3T |

| Color different | ΔE<=2.0(follow color sample) | ΔE<2.0 |

| Pencil hardness | >=HB | >=HB |

| Chemical resistance | 5%HCI or 5% NaOH test in 24 hours -No change;ASTM D1308 | No change |

| Coating adhesion | >=1grade for 10*10mm2 gridding test | 1grade |

| Resist solvent | No change for 200 times(MEK) | No change |

| Boiling water resistance | Coating no tear off for 2 hours | No TEAR OFF |

| Peeling strength/stripping strength | Average >=7N/mm of 180oc peel off for panel with 0.5mm alu.skin | 7N/mm |

| Impact test for paint | 50KG.cm impact-paint no split for panel | No split |

| Abrasion resistance (L/Mil) | ASTM D968 | 44 |

| Temperature resistance | -40ºC to +80ºC temperature without change of color difference and paint peel off,peeling strength average dropprate <=10% | Change of glossy only,no paint Peel off |

| Coefficient of linear Thermal Expansion | 100ºC temperature difference | 2.4mm/m |

| Detergent resistance (3%) | ASTM D2248 | No change |

| Humidity Resistance (3000hrs,100%RH,100°F) | ASTM D2247 | No change |

| Salt spray resistance (3000hrs,5% salt) | ASTM B117 | No change |

| Resistance to Staining | 4000h radiate in 800W/m2 in humidity condition,glossiness deviation less grade 2,color difference <=4.0 | No change |

MOQ:1000sq.m.If in stock,can be less.

Sample Management:Free sample with courier freight collected.Also sample freight can be deducted in the signed orders.

Size and Color:Customized size and color accepted.

Customized Color match Procedures:

1).Customers provide color samples or color code in Panton or RAL color chart.

2).Neitabond provide new painted color samples.

3).Customers confirm the color code after receiving.

4).Place order and make production.